Reverse osmosis is a process in which water (solvent) passes under pressure through a semi-permeable membrane, becoming less concentrated and losing dissolved substances in itself.

The reverse osmosis process has been in use since the 1970s. Originally it was used for seawater desalination, but today it is used for various purposes: preparation of feed water for steam boilers, preparation of water for the food and pharmaceutical industries, waste water treatment and preparation of drinking water.

Advantages and disadvantages of using reverse osmosis membranes

Advantages and disadvantages of the result of drinking water treatment with such technology are determined by its peculiarities and filtration purposes, which depend on the initial water parameters. The possibility to purify water by demineralizing it and bringing it to the state of distillate allows to use such a product for medical, laboratory and pharmaceutical purposes. For the purpose of domestic use, water containing microelements is recommended for drinking purposes. WHO does not give the recommended level of mineralization of drinking water, but according to organoleptic indications recommends a limit of total mineralization of drinking water of 1000 mg/l. Low mineralized water contains less than 200 mg/L of salts. Much depends on the homeostasis of each person, so the choice of reverse osmosis membrane for the purification of drinking water needs an individual approach.

Principle of operation

The reverse osmosis unit of industrial type consists of the following equipment: fine filter, reagent preparation system, high pressure pump, block of filtering modules, sensors and control devices.

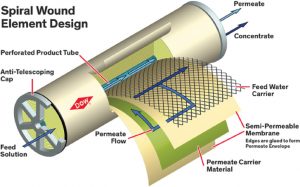

The basis of the reverse osmosis unit is a semi-permeable reverse osmosis membrane in a housing. It receives raw water, at the output we get purified demineralized (permeate) and water – concentrate with impurities (discharged). Under high pressure created by the pump (rotary or centrifugal multistage) the water is pressed through the membrane. Dose and apply sediment inhibitors (to slow the formation of unwanted deposits on the membranes) and chemical flushing systems (to remove sediments from the membrane surface).

Quality Control Inspection. To control the quality of purification and pH – flow salt meters and pH-meters. For controlling the flow of permeate and concentrate – flow meters. The reverse osmosis system can be controlled in a semi-automatic or automatic mode. You can check the quality of the reverse osmosis membrane with a TDS meter.

On average, a reverse osmosis membrane purifies water at a molecular level of 10-9 m (1 nm).

The following reverse osmosis membrane manufacturers are presented in Ukraine: Toray, Dow Filmtec, GE OSMONICS and Hydranautics.

When selecting a reverse osmosis membrane, it is necessary to rely on its main characteristics:

- selectivity: the level of purification is expressed as a percentage, the selectivity values of industrial membranes vary from 99.0% to 99.8%;

- capacity: the volume of water purified in a certain time at certain values, measured in cubic meters / day or GPD, depends on the size of the membrane, the filtering area, selectivity;

- pressure: high (14-16 bar) and low (8-10 bar) pressure – determines the pressure level at which the water has to be supplied to the membrane, it is selected according to the mineralization index

- size: there are two basic standards for industrial reverse osmosis membranes – 8040 and 4040. The first two digits define the diameter of the membrane in tenths of an inch, the last two digits define the length in inches. There are also other sizes: 4021, 2540, 2521.

In the end, it is always better to trust the professionals.

Specialists of the company Aquarum will always take into account your wishes, suggestions, help in the selection and purchase of reverse osmosis membranes.